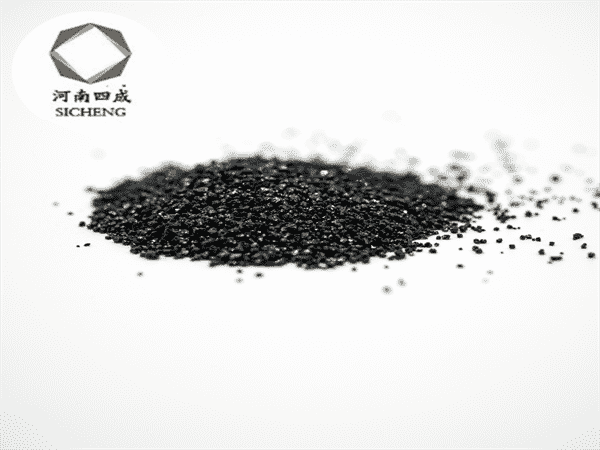

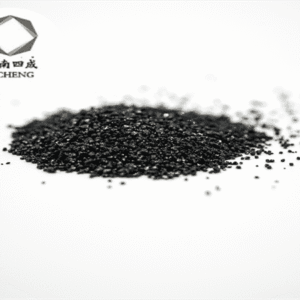

AFS45-55 Chromite Sand Casting Sand

Chromite sand is a specialized foundry sand used in sand casting due to its unique properties. Here’s what you need to know:

1. What is Chromite Sand?

-

A naturally occurring chrome-based refractory sand (FeCr₂O₄).

-

High melting point (~2,150°C / 3,902°F).

-

High thermal conductivity (faster cooling than silica sand).

-

Chemically inert, resistant to metal penetration.

2. Advantages in Sand Casting

✔ Heat Resistance – Excellent for high-temperature alloys (steel, stainless steel, high-chrome iron).

✔ Low Thermal Expansion – Reduces veining and burn-in defects.

✔ Good Flowability – Easy to ram and mold.

✔ Reduces Silica Hazards – No risk of silicosis (unlike silica sand).

3. Common Applications

-

Cores & Molds – Used in contact with molten metal for better surface finish.

-

Backing Sand – Mixed with silica or zircon sand to reduce costs.

-

Large Castings – Helps control solidification rates.