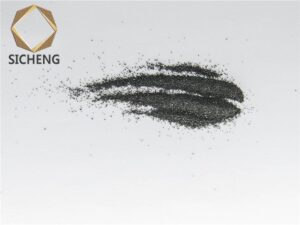

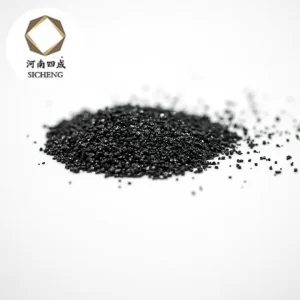

Foundry Chromite sand

Casting Chrome ore sand is a kind of foundry sand with high refractoriness. The content of chromium oxide of casting chromite sand should be at least 46%. That will get high Solid-phase sintering temperature. Chrome ore sand is especially featured with its high thermal conductivity. It can not only make the casting steel cool quickly, but also prevent casting iron& steel from sand-sticking.

Foundry Chromite sand Features:

1. High melting point, high sintering temperature

2. Excellent thermal stability

3. High density, high density

4. Medium Mohs hardness 5.5

5. High thermal conductivity

6. Low coefficient of thermal expansion

2. Excellent thermal stability

3. High density, high density

4. Medium Mohs hardness 5.5

5. High thermal conductivity

6. Low coefficient of thermal expansion

|

Content

|

Guarantee Value

|

Typical Value

|

|

Cr2O3

|

≥ 46%

|

46.50%

|

|

SiO2

|

≤ 1.0%

|

0.61%

|

|

FeO

|

≤ 28%

|

26.8%

|

|

Cr:Fe

|

≥1.5:1

|

1.55

|

|

MgO

|

≤ 10%

|

9.8%

|

|

CaO

|

≤ 0.3%

|

0.3%

|

|

Al2O3

|

≤ 15.5%

|

15.4%

|

|

P

|

≤30 ppm

|

28 ppm

|

|

S

|

≤30 ppm

|

27 ppm

|

|

Mohs Hardness

|

5.5-6

|

|

Melting Point

|

2180 ℃

|

|

Sintering Point

|

>1800℃

|

|

Specific Gravity

|

4.0-4.8 g/cm3

|

|

Bulk Density (LPD)

|

2.5-3 g/cm3

|

|

Color

|

Black

|

|

PH Value

|

7-9

|

|

Thermal conductivity

|

0.63 W/M·K

|

|

Thermal Expansion Rate(1000℃)

|

0.6%

|

|

Acid Demand Value (ADV)

|

PH3:≤ 3ML

PH4: ≤ 2ML PH5: ≤ 2ML |

|

Turbidity(NTU)

|

≤ 200

|

|

Soil content

|

≤0.1%

|

|

Moisture

|

≤0.1%

|