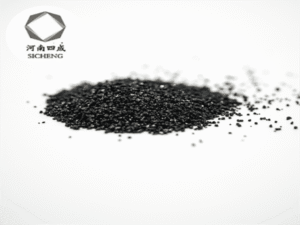

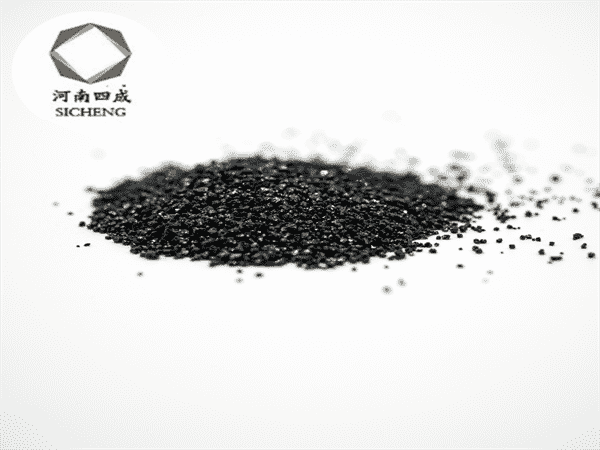

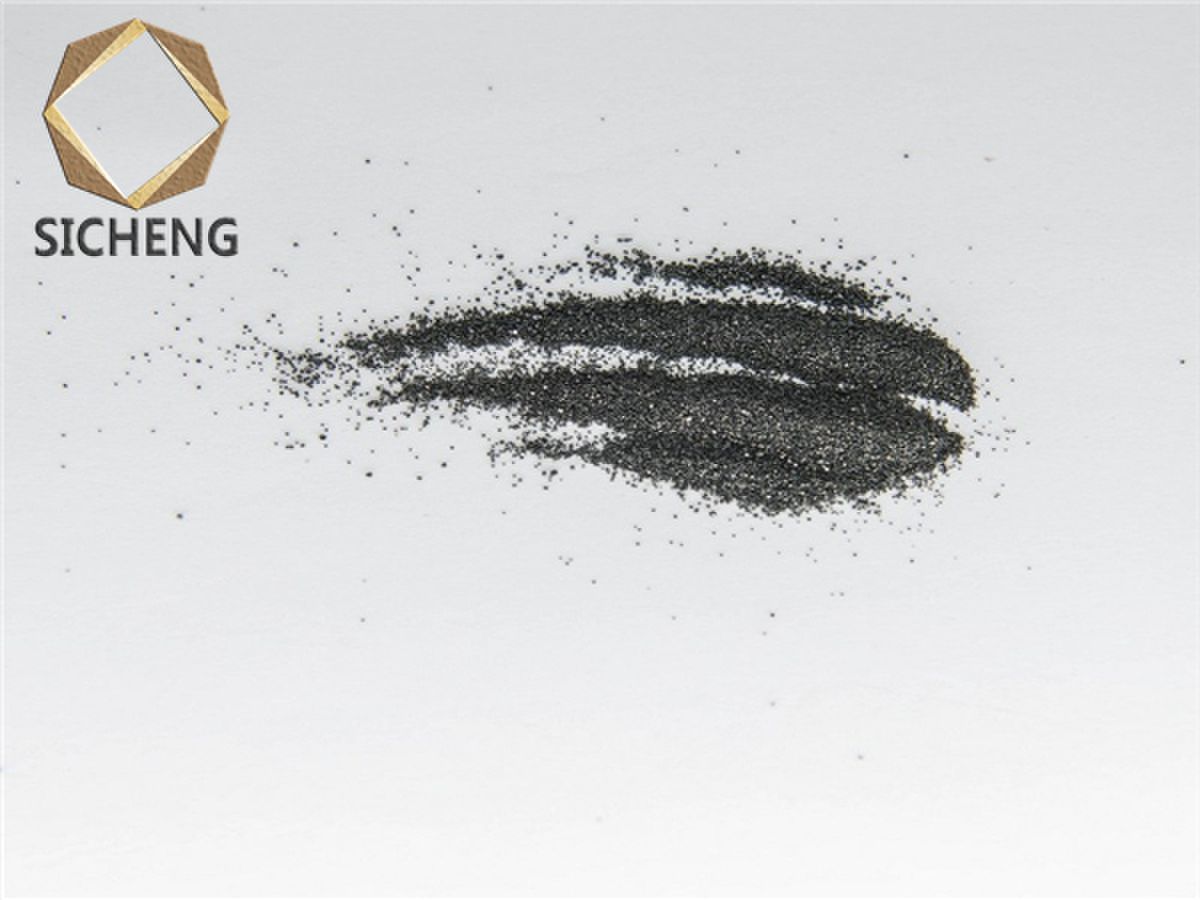

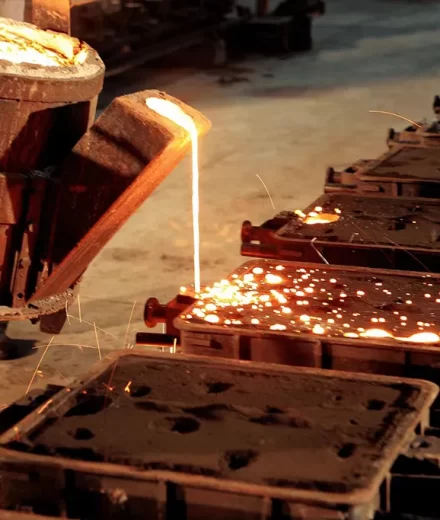

Chromium ore sand is a special foundry sand made primarily from natural chromite, processed through crushing, screening, and other processes. The general production process is as follows:

Specific details are as follows:

Washing: The chromium ore raw material is washed with water and then screened through a drum screen to remove mud and impurities.

Drying: The washed raw material is dried to remove moisture, preparing it for subsequent processing.

Vibrating Screening: The dried raw material enters a vibrating screen to separate the particle size required by the customer, meeting the needs of different application scenarios.

Magnetic Separation for Iron Removal: The screened raw material undergoes magnetic separation to remove impurities such as iron and silicon, improving the purity of the chromium ore sand, achieving a chromium content of over 46% and a silicon content of below 1%.

Packaging: The magnetically separated chromium ore sand is packaged to obtain the finished product.