Chromite sand (chromite ore sand) is an important foundry refractory material and metallurgical raw material. Its core production process involves removing impurities from raw chromite ore, enriching chromium oxides, and processing it into particle sizes that meet application requirements. The following is a detailed production process flow chart and explanations of each step:

I. Core Process Flow: Raw Chromite Ore → Crushing → Screening → Grinding → Separation (Enrichment) → Dehydration and Drying → Grading and Shaping → Inspection and Packaging → Finished Chromite Sand

II. Detailed Explanation of Each Step:

1. Raw Material Preparation: Pretreatment of Raw Chromite Ore

Raw Material Source: Mainly from chromite deposits (such as magmatic chromite and placer chromite). The grade of the raw ore varies greatly (Cr₂O₃ content is usually 10%~40%). Associated impurities include silicate minerals (pyroxene, olivine), iron oxides, alumina, magnesium oxide, etc.

Pre-treatment steps:

1. Manual sorting: Remove large pieces of waste rock and soil lumps from the raw ore;

2. Washing (optional): For raw ore with high mud content, use a washing machine (spiral washer, trough washer) to wash away surface-adhered mud and sand, preventing subsequent equipment blockage.

3. Crushing: Reduce particle size and liberate valuable minerals. The purpose is to crush large pieces of raw ore to a suitable grinding size, initially liberating chromite (high density, high hardness) from gangue minerals (low density, low hardness). Crushing Equipment Combination (Three-Stage Closed-Circuit Crushing):

Coarse Crushing: Jaw Crusher, crushing raw ore (maximum particle size 500~800mm) to 100~150mm;

Medium Crushing: Cone Crusher/Impact Crusher, crushing to 20~50mm;

Fine Crushing: High-Efficiency Cone Crusher/Impact Crusher, crushing to below 5~10mm;

Closed-Circuit Circulation: The product after fine crushing is screened by a vibrating screen. Unqualified coarse particles are returned to the fine crusher for re-crushing to ensure uniform particle size.

Key Requirements: Avoid over-crushing (to prevent excessive load on subsequent grinding), control iron contamination during crushing (using wear-resistant liners to reduce impurities generated by equipment wear).

3. Screening: Pre-treatment for Classification

The crushed product enters a multi-layer vibrating screen (usually 3-4 screens) for particle size classification:

Coarse particles (>10mm) are returned to the fine crusher;

Undersized particles (<10mm) enter the grinding stage;

If the raw ore grade is high (Cr₂O₃>35%), coarse-grained chromite sand (e.g., 1-5mm) can be directly screened, requiring no further separation, only drying and shaping.

4. Grinding: Deep Liberation of Minerals

The purpose is to grind the screened ore particles finely, completely liberating the chromite crystals from the gangue minerals (liberation degree ≥90%), creating conditions for subsequent separation.

Grinding equipment: Ball mill (grid-type ball mill + overflow-type ball mill combination), rod mill;

Grinding parameters: Grinding concentration 60%~70%, grinding time adjusted according to target particle size (usually grinding to -200 mesh, 30%~60%);

Closed-circuit grinding: Grinding products are classified by classifiers (spiral classifier, hydrocyclone), coarse particles are returned to the ball mill for regrinding to ensure effective liberation.

5. Separation (Enrichment): Improving chromite grade. A core step, separating impurities based on the differences in physical properties (density, magnetism, conductivity, etc.) between chromite and gangue minerals to increase Cr₂O₃ content (target grade typically ≥45%, high-end foundry sand ≥50%). Mainstream separation processes (used in combination depending on the properties of the raw ore):

Gravity separation (most commonly used): Separates chromite (density 4.3~4.8 g/cm³) from gangue (density 2.6~3.2 g/cm³);

Equipment: Jigs (for coarse particles), shaking tables (for fine particles), spiral sluices (for medium and fine particles);

Process: Grinding products are first roughed by jigs to obtain rough concentrate and tailings; the rough concentrate is then further refined by shaking tables to obtain high-grade concentrate.

Magnetic separation: Utilizes the magnetic difference between chromite (weakly magnetic) and some gangue (non-magnetic);

Equipment: Wet permanent magnet drum separator, high-gradient magnetic separator;

Application: Further purification of concentrate after gravity separation (removal of residual magnetic gangue), or processing of strongly magnetic chromite ore.

Electrostatic separation (auxiliary): Utilizing the difference in electrical conductivity between chromite and gangue, this method is used for the deep purification of fine-grained concentrates.

Equipment: High-voltage electrostatic separator, suitable for fine-grained products down to -0.074mm.

Separation parameters: Concentrate Cr₂O₃ grade ≥45%, recovery rate ≥70% (recovery rate can reach over 85% for high-quality raw ore); Tailings Cr₂O₃ content ≤5%, can be used as building aggregate or disposed of as waste.

6. Dehydration and drying: Removing moisture. The separated concentrate is a wet slurry (moisture content 20%~30%), which needs to be dehydrated and dried to moisture content ≤0.5% (to avoid clumping during storage and affecting use).

Dewatering Steps:

Concentration: A thickener is used to increase the slurry concentration to 50%~60%, reducing drying energy consumption.

Filtration: A plate and frame filter press or vacuum filter is used to filter the slurry into a filter cake (moisture content 10%~15%).

Drying: A rotary dryer or fluidized bed dryer is used at a drying temperature of 120~200℃, resulting in a moisture content ≤0.5%.

7. Grading and Shaping: Adjusting Particle Size

Based on the application (casting, metallurgy, refractory materials, etc.), the dried concentrate is processed into products with a specific particle size range.

Grading: High-frequency vibrating screens and air classifiers are used to grade sand according to customer requirements (e.g., common particle sizes for foundry chromite sand: 10-20 mesh, 20-40 mesh, 40-70 mesh, 70-140 mesh, etc.); Shaping (optional): For high-end foundry sand requiring rounded particles and fewer sharp edges, impact shaping machines or ball mills are used for light grinding to remove particle sharp edges and improve flowability; Dust removal: Dust generated during grading and shaping is collected using bag filters to prevent pollution.

8. Inspection and Packaging: Ensuring Product Quality

Quality Inspection:

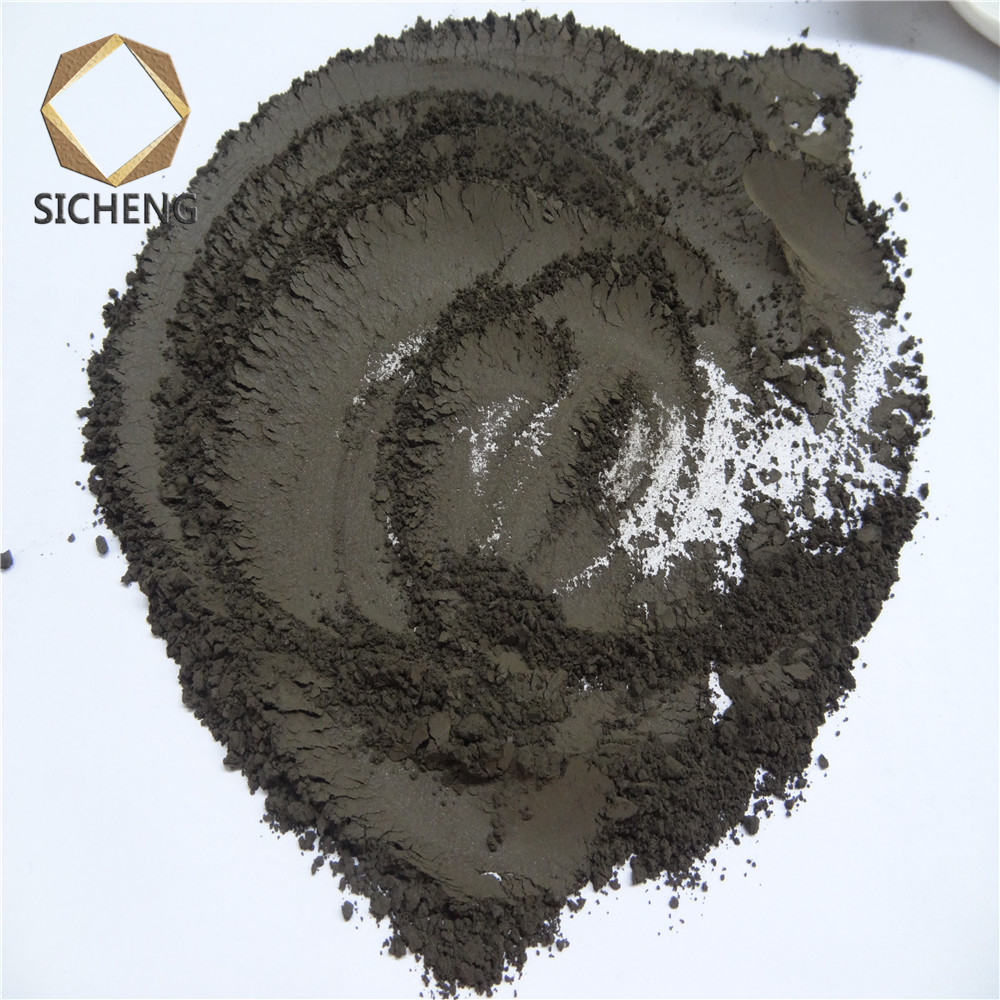

Chemical Composition: Testing for Cr₂O₃, FeO, Al₂O₃, SiO₂, and MgO content (casting sand requires SiO₂ ≤ 3% to avoid gas generation during casting);

Physical Properties: Testing for particle size distribution, density, Mohs hardness (≥ 6.5), refractoriness (≥ 1900℃), and acidity/alkalinity (alkaline);

Appearance: Free from obvious impurities and lumps, with a uniform color (dark gray or black).

Packaging: Packed in woven bags (25kg/bag) or ton bags, sealed and stored to prevent moisture absorption.

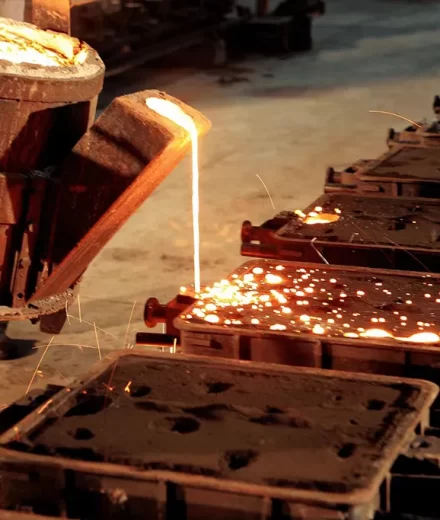

III. Process Differences in Different Application Scenarios

Application Area | Core Requirements | Process Focus

Foundry Chromium Ore Sand | High grade (Cr₂O₃≥50%), low SiO₂, uniform particle size, good flowability | Gravity separation + magnetic separation purification, shaping treatment, strict control of SiO₂ content

Metallurgical Chromium Ore Sand (Smelting Ferrochromium Alloys) | High Cr₂O₃, high Cr/Fe ratio (≥1.5) | Gravity separation as the main method, no need for fine classification, ensuring recovery rate

Refractory Chromium Ore Sand | High refractoriness, low impurities | Magnetic separation + electrostatic separation purification, control of Al₂O₃ and CaO content

IV. Key Technical Points

Liberation Control: The grinding process must ensure complete liberation of chromite from gangue, otherwise the separation efficiency will drop significantly;

Grade Adjustment: Through multi-stage separation (roughing – cleaning – finishing) (Sweeping and sorting) Balancing grade and recovery rate to avoid excessive pursuit of grade leading to excessively low recovery rates; Impurity removal: Focusing on removing SiO₂ (for casting) and CaO (for refractory materials) to avoid affecting product performance; Particle size control: Precisely classifying according to the application scenario to avoid excessively coarse or fine particle size (e.g., excessively fine foundry sand will result in poor air permeability).

V. Environmental and Safety Precautions Dust generated during crushing, grinding, and grading processes requires corresponding dust removal equipment (bag filters, electrostatic precipitators) to avoid dust pollution; Wastewater generated from washing and sorting should be recycled after sedimentation in a settling tank to avoid external discharge; Chromite ore itself is non-toxic, but long-term exposure to dust may cause respiratory discomfort; operators must wear dust masks; Tailings must be centrally stockpiled and can be used for comprehensive utilization such as brick making and roadbed filling to avoid environmental pollution.

Through the above processes, chromite ore can be processed into high-grade, high-quality chromite sand products to meet the application needs of casting, metallurgy, and refractory materials industries.