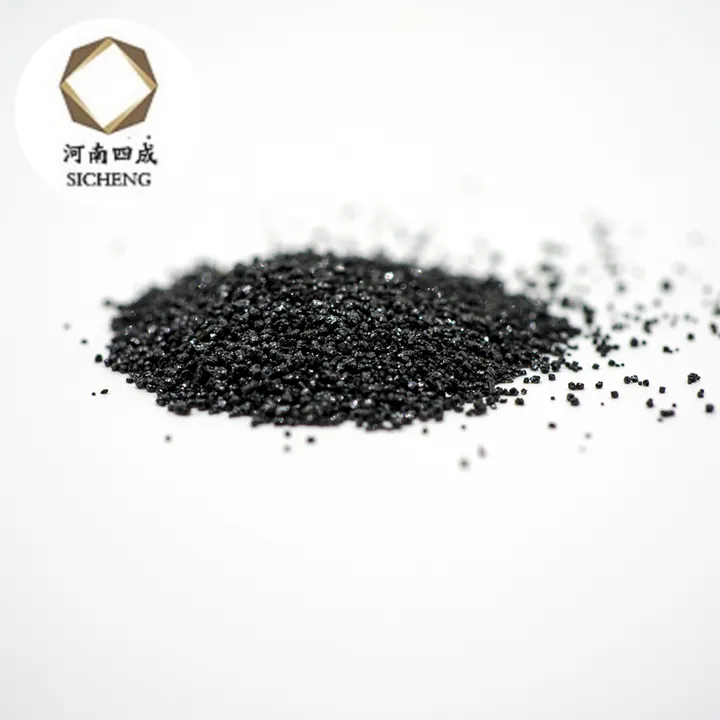

Chromite sand AFS45-55

Chrome Ore/ Chromite Sand, also known as chromite ore, is a special sand for foundry. It is a natural spinel dominated by chromite. After crushing, grinding and sieving, it is divided into prescribed grain size, and is suitable for sand for moulding (core-making).

Characteristics

1. Heated Volume Stability

2. High thermal conductivity

3. Strong alkali resistance

4. Solid phase sintering, non-sticking sand

Technology–Chrome ore price

|

Item |

Unit |

Index |

|

Cr2O3 |

% |

≥46.0% |

|

SiO2 |

% |

≤1.0% |

|

FeO |

% |

≤26.5% |

|

CaO |

% |

≤0.30% |

|

MgO |

% |

≤10.0% |

|

Al2O3 |

% |

≤15.5% |

|

P |

% |

≤0.003% |

|

S |

% |

≤0.003% |

|

Cr/Fe |

|

1.55:1 |

|

Bulk Density |

g/cm³ |

2.5-3 |

|

Color |

/ |

Black |

|

PH |

/ |

7-9 |

|

The amount of the acid |

/ |

≤ 2 ML |

|

Percent soil |

% |

≤0.1 |

|

Percent Moisture |

% |

≤0.1 |

|

The sintered |

℃ |

1600 |

|

Percentage of free acid present in the sand |

% |

0 |

|

Filling density |

g/cm³ |

2.6 |

|

Sintering point |

°C |

> 1,800 |

|

Melting temperature |

°C |

2,180 |

|

Packing |

MT |

1 big bag |

|

Sizes |

|

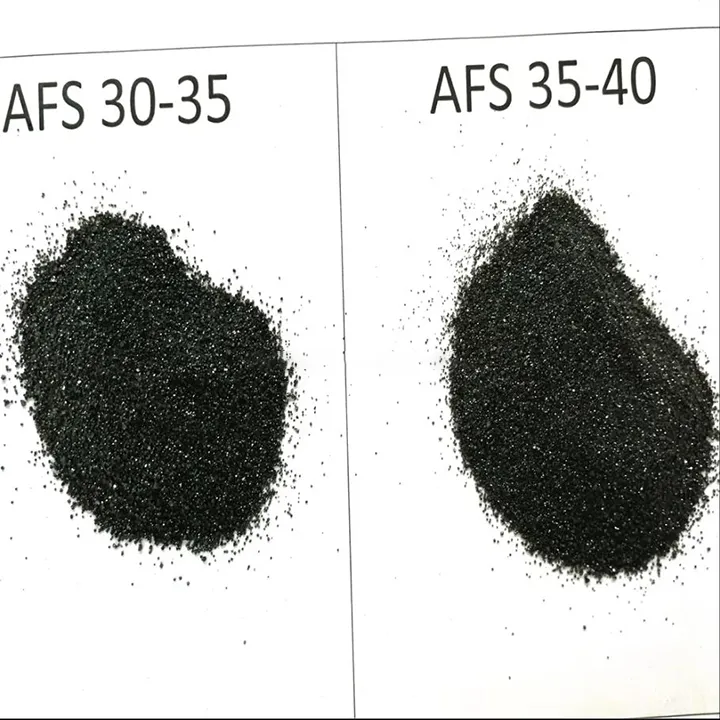

AFS30-35 35-40 40-45 45-50 |

Application

Chromite Sand in the foundry industry

Its properties enable the material to be used in high duty grey iron and steel foundries as core and mould making sand. Its high thermal conductivity gives it good chilling properties, low thermal expansion gives rise to good dimensional stability. Its basicity being close to neutral allows the use of a wide range of resin bonding systems and inorganic binders, it has a high refractoriness and a broad sieve distribution.

Chromite Sand in the steel industry

In steel production, Chromite Sand is used as well filler for protection of the sliding gate in large steel holding ladles.

Chromite Sand in the glass industry

When ground to a fine flour, Chromite Sand is used for the production of green glass beverage containers.

Henan SiCheng Abrasives Tech Co., Ltd

◊Henan SiCheng Abrasives Tech Co.,Ltd was founded in 1999, specifized in produdtion of white/brown/black/pink/zirconia fused alumina, black/green silicon carbide, boron carbide, chromite sand,etc. Mainly used for sandblasting,abrasive tool,refractory,foundry industry.

◊We own our own science management system and perfect quality control system with high-tech testing equipment such as omec particle size analyser, slap-sieve ,microscope and so on.

◊In order to serve our international customers better and make our materials to global market widely, we established henan sicheng abrasives tech co.,ltd in 2009, which specifized in international business in blasting,refractory, foundry fields.

Refractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sandRefractory and metallurgical grade chrome ore chromite sand

FAQ

1. Q: How to place an order?

A: Send the inquiry — Get the quotation — Approve the order — Make the PI — Payment — Arrange production & inform — Rest and relax — Finished products inspection — Make the balance — Arrange delivery — Goods received.

2. Q: What kind of payment do you accept?

A: Formal order we usually choose TT or L/C, Western Union,Paypal for small amount payment.

3. Q: Do you offer OEM service?

A: Yes, Oem is ok, our factory can offer produdcts that according to our clients’ requirments.

4. Q: How long is the delivery?

A: Usually 3-5 days for small order, 10-20 days for bulk order after payment received.